Why Choose Catz Design Farm for your printing needs

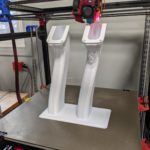

- I run 18 FDM printers here at Catz Design Farm. I can handle most materials including HTPLA, PETg, ABS, ASA, PC blend, TPU, and have experimented with PP and BASF ultrafuse. I currently do not have the capability for high temp PEI pure PC or some of the other high temp exotics.

- I can print carbon fiber filled materials and frequently use CF PETg by atomic for high strength parts. From partnerships with other small businesses, I can also arrange parts to be done with HP Multijet Fusion , Polyjet and SLA technologies.

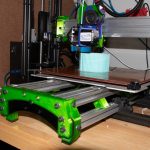

- My print farm can handle everything from small detailed parts on .3mm nozzle toolheads to large parts on the 475mm hypercube. I also have a Delta that can do 20" tall by almost 12 inch diameter. The main fleet consists of machines by Lulzbot.

- Featuring printers from Lulzbot, SeemeCNC, BD3D Hypercube, Eryone and Anycubic machines.